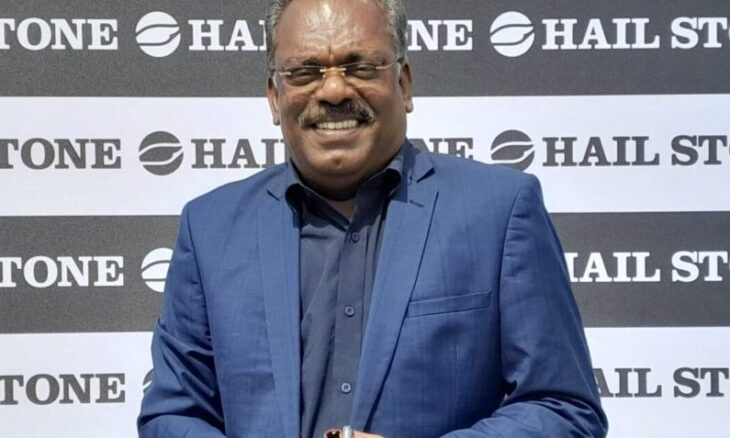

Step into the world of cutting-edge innovation with P L Muthusekkar, Chief Operating Officer of Hailstone Innovations Pvt Ltd. In an exclusive interview, he shares insights into Hailstone’s revolutionary products, the long-standing partnership with EXCON, and the ambitious global journey that lies ahead for this Rs 300 crore powerhouse in industrial equipment and machinery manufacturing.

Could you please offer information about your current association with the trade show? As one of the prominent sponsors, can you elaborate on the value you place on this partnership? Additionally, could you provide insights into your experience at the exhibition and highlight some of the products your company has on display?

For years, Hailstone has been a consistent participant at EXCON. In the last two editions, we elevated our presence as both associate and principal sponsors, witnessing positive outcomes. Held in the bustling southern part of India, Bangalore proves ideal for construction activities, attracting numerous OEMs and construction equipment companies. Despite some logistical challenges, we’ve recognized the inherent value and accepted them as part of the process. Our commitment to the trade show remains steadfast.

What is the feedback you have received from visitors about the event?

Unlike the last time when we had heavy rains the weather has been supportive. The environment has been favourable for business people looking out to invest, the turnout of exhibitors and visitors has been good. The trade show has been very productive and a win-win situation for the participants.

As a company what are the factors which inspire such confidence for companies such as yours?

Beyond the political backing for events like EXCON, our confidence stems from the on-the-ground conditions, primarily driven by the inquiries and business dynamics. Notably, the robust state of infrastructure development is a key indicator. Both government and private initiatives, encompassing the construction of new airports, dams, bridges, roads, buildings, and malls, are flourishing. This surge in activities directly correlates with the increasing demand for construction materials such as stones, aggregates, and sand. Furthermore, the expanding railway network further amplifies the need for our products, aligning seamlessly with our production ambitions. The thriving growth in these sectors substantiates our optimism and provides a solid foundation for sustained business success.

Market projections reflect a growing demand for products such as those manufactured by Hailstone, with a shift towards mobile equipment such as track-mounted and plant-on-wheel solutions. The industry is witnessing a migration to larger capacities, exceeding 200 ton and reaching up to 350 ton.

Can you highlight your experience at the exhibition and talk of the products displayed?

Yesterday (12th December) was particularly successful for us at EXCON with a significant influx of visitors from India and abroad. Nitin Gadkari, Union Minister of Road Transport and Highways, graced the event, launching one of our products. With seven planned launches and a focus on innovation, our flagship product, the Plant on Wheels, took center stage. Unlike traditional stationary equipment, this complete plant on wheels offers unparalleled advantages. Eliminating the need for a fixed foundation, it enhances mobility, allowing a road contractor to efficiently move the crusher within short distances, aligning perfectly with government and infrastructure needs. The Plant on Wheels boasts swift commissioning, taking only 2 or 3 days compared to the 25-30 days required for stationary plants. This results in a productivity boost of over 20 days. Additionally, it reduces construction costs by eliminating the need for a civil foundation, requires minimal electrical cable, and consolidates maintenance in one location. The mobility factor caters to contractors working across borders or states. In an industry where rental business is traditionally low, especially in the crusher sector, this innovation marks a significant breakthrough.

What are the other innovative products offered by your company?

Our innovations align seamlessly with our ambitions in the road sector. Hailstone has pioneered the concept of a complete plant, integrating jaw, cone, and screen on one chassis. Beyond that, our commitment to pioneering solutions is evident in various projects reflecting our commitment to sustainable and efficient solutions. Notably, we’ve successfully converted coal overburden material into sand, addressing the environmental impact of mining operations. In the western coal fields in Nagpur, this transformation has already taken place. Expanding our horizons, we’ve tackled the challenge of sea sand with a specialized plant designed to convert it into a construction-friendly material, overcoming the inherent salt content. Furthermore, our successful venture into dam mining stands out. With many dams facing issues of accumulated waste and mud, our innovation involves excavating and utilizing this material to enhance the storage capacity of dams. This process not only aids in flood prevention but also contributes to improving the overall quality of water, as well as fortifying the walls and banks of the dam.

Could you provide insights into Hailstone’s manufacturing facilities, their capacities, current performance and market projections for the coming years?

Hailstone Innovations specializes in crushing, mining, screening, washing, and recycling solutions. It is a 29-year-old Indian company originating in Thrissur, Kerala, a hub of entrepreneurship, which proudly epitomizes the spirit of ‘Make in India.’ Our expansive facility at Kanjikode at Palakkad spans approximately 2,00,000 sqft, serving as the hub for comprehensive assembly, including jaw, cone, screens, VSI, and track plants. Regarding our footprint, besides the Palakkad facility, we maintain feeder units established in 1994, which continue to operate. These feeder units complement our final assembly and testing plant in Palakkad. In terms of future investments, we are actively enhancing our service network across India and neighboring countries. Additionally, plans are underway to establish a new plant.

In terms of our performance, 2022 saw a remarkable 39 per cent growth, and as of December 2023, we expect to surpass 50 per cent growth, with a turnover exceeding Rs 300 crore. The outlook for 2024 is promising; we aim to surpass previous turnover milestones. We expect to see exports growing up. We changed our logo looking at the global positioning. Looking ahead, Hailstone’s vision is not only to be an infrastructure leader in the country but also on the international stage.